Portfolio

-

![]()

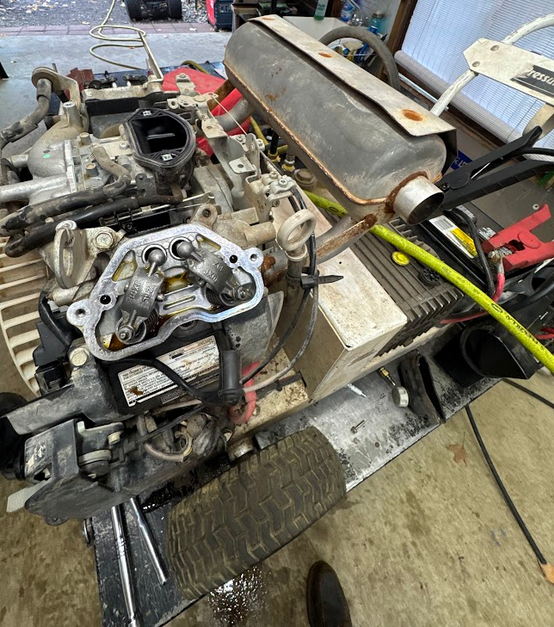

Honda pressure washer getting the valves adjusted.

Overtime valves can bend, get damaged, valve seats can pull out of the head. But they mostly just come out of spec or adjustment due to age and general use. Between general maintenance we adjust the valves to spec.

-

![]()

Snowblower with really old gas.

Most of the time snowblowers, and lots of other equipment come in with old gas in it. Old gas can harden up and clog up your fuel lines and jets in your carburetor, and will cause it to stop flowing. If you are getting gas, and the gas is darker yellow or green or smells like turpentine, it will not fire. In either of these cases if the carburetor is salvageable it will be cleaned, otherwise it is replaced with new.

-

![]()

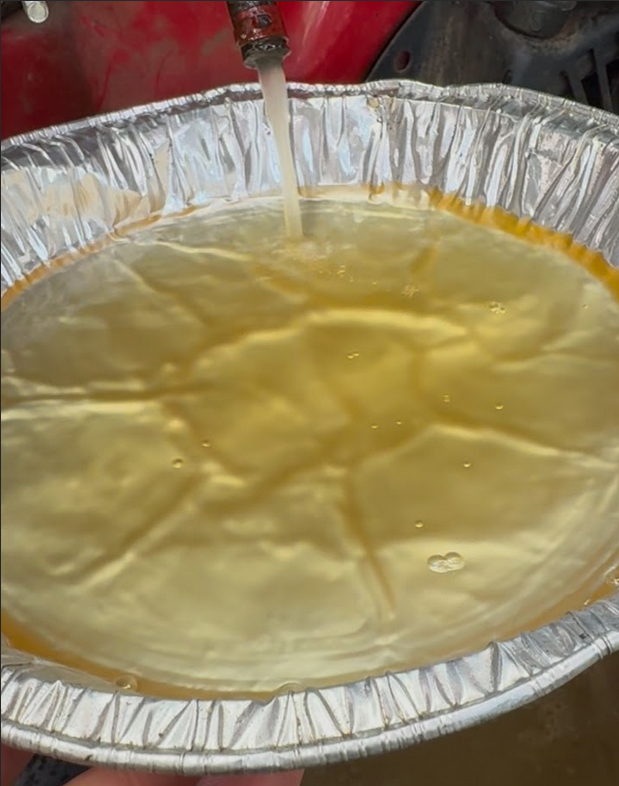

Old gas in carburetor.

This gas I can smell through the screen. The smell of turpentine is strong when your gas is this color. In this case the carburetor was salvageable, not a lot of corrosion, just old gas. 30 minutes to an hour in our ultra sonic cleaner at 180 degrees Fahrenheit, and she is good to go.

-

![]()

More bad gas!

You can see how this gas is very cloudy, white looking, also having that darker yellow shine. So on the verge of going bad and has a bunch of water in it! if you let that settle it will separate at the bottom of the container and you would see the water bubbles clearly. Make sure to check your fuel!

-

![]()

Mower with an old, cracked, dry rotted drive belt.

Belts get old and they harden and crack. Sometimes bad pulleys and bad belt guides can wear belts quicker or throw them off a lot.

-

![]()

Chainsaw taken apart for new carb and fuel lines.

A lot of these little carburetors don’t take much but one grain of sand for it to run bad. But most of the time these carbs are replaced as it is barely worth paying labor to clean them then to it is to get a brand new one and install it. In this case you can see his fuel lines were old looking and the bottom one was dry rotting.

-

![]()

Snowblower split apart to install new auger drive belt and auger pulley.

All 2 & 3 stage snowblowers split apart in the middle to separate the impeller/auger housing from the unit. This opens up to where your belts, pulleys, tensioners, springs, and auger are.

-

![]()

Engine that has been taken out and splitten apart to replace cam because the compression release broke off.

A common problem with today’s single cylinder cams are the compression releases breaking. That can cause slow cranking and or none at all. Which therefore can damage other components such as a starter and excessive draw on the battery.

-

![]()

Rodent nest's on a head of an engine.

Rodent nest’s can cause overheating and can ruin heads. Doesn't allow the head to breathe or cool down. Lots of people don’t realize they are there until their mower starts acting up.

-

![]()

Brass worm gear for auger on a snowblower has been shredded.

Brass worm gears are common to go out and can wear quickly because the material is softer and it is against a steel worm gear. If an auger isn’t turning and the shear pins are still intact then usually the issue is the worm gear.